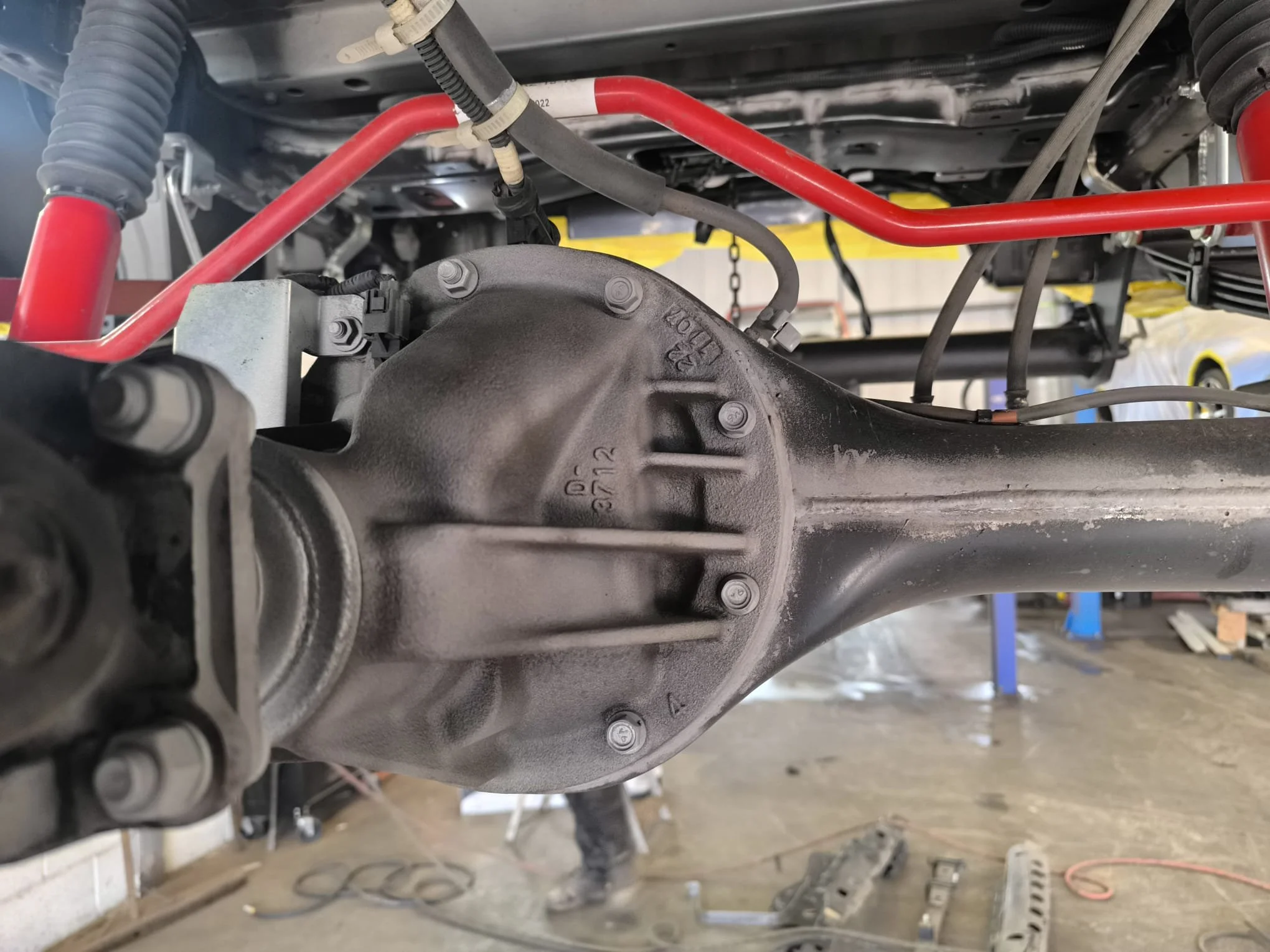

2023 Izuzu D-MAX

Model: 2023 #izuzu D-MAX

Use Case: general purpose vehicle

Customer Concern: corrosion on chassis and suspension components, long-term protection required for UK climate

What We Did

The D-MAX came to us with light to moderate surface corrosion across the chassis, generally welded seems, – typical of vehicles used on UK roads, especially during winter months. this vehicle also had x2 types of wax applied (poorly) by the dealer The owner wanted a comprehensive solution that not only restored the appearance but provided lasting protection for years of use.

Our restoration process included:

Thorough Dry Ice Blasting+ shot blasting

We started with a full dry ice blast to strip away dirt, grime and old coatings, Then used a more abrasive blasting technique to remove all corrosion back to bright, clean steel.Detailed Inspection & Surface Preparation

With the underbody fully exposed, we inspected all components and prepared the full underbody for coating.Protective Primers

We applied a marine grade, anti corrosion epoxy primer to all blasted areas, providing a stable surface for future proofing.IGL aegis anti-corrsion system

The entire chassis and suspension were coated with our premium, 2k aegis, a graphene infused anti-corrosion clear coat with outstanding durability for up to 15 years. alsousing a combination of cavity waxes for long-term durability.Final Detailing

Components were masked where necessary to ensure a neat finish. Brake lines, fixings, and vulnerable fittings were all treated with care.